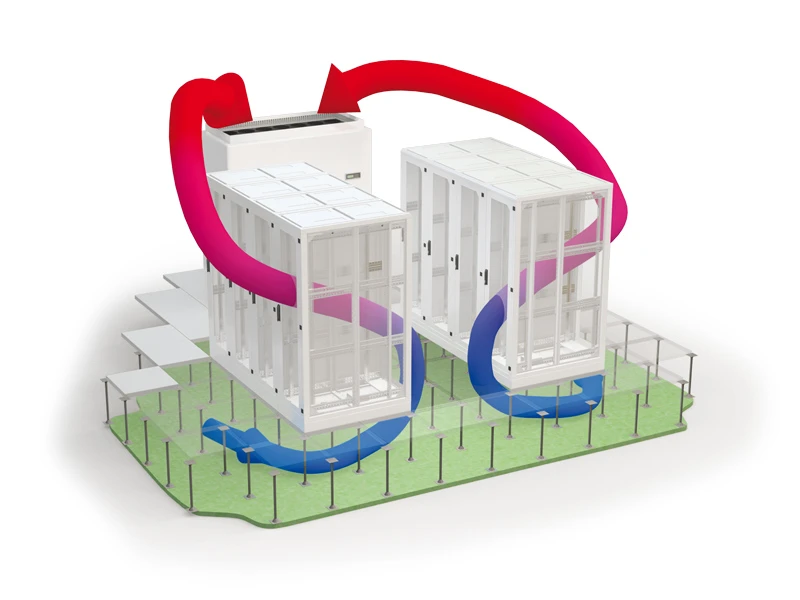

This solution optimizes the use of cold air by transporting it from the double floor to the installed equipment.

A deflector, located at the bottom of the cabinet, directs cold air to the front of the cabinet.

This solution optimizes the use of cold air by transporting it from the double floor to the installed equipment. The cabinet is mounted on a special adjustable welded frame, which replaces the 600 × 600 mm floor tile. A deflector, located at the bottom of the cabinet, directs cold air to its front part.

Cool air is kept at the front of the cabinet by a solid door, which can be glazed or all-metal, depending on preferences. After passing through the servers, hot air is exhausted into the hall. The expanded metal door (86% perforation) ensures the highest possible level of air exhaust from the cabinet.

An air inflow regulator can be used to control the amount of air or to shut it off completely when no equipment is installed in the cabinet.

One of the biggest advantages of the system is flexibility in floor planning. Placement of cabinets in hot and cold aisles is no longer required as the hot and cold air is separated inside the cabinets.

Direct cooling of the cabinet requires the use of a separation frame and blanking panels to achieve efficient air flow.

The cooling system with air supply from the floor and exhaust to the hall optimizes the use of the cool air inside the cabinet as it flows from the double floor directly to the installed technologies.

Technical information

| Parameter | Value |

|---|---|

| Recommended configuration of cooling with air supply from the floor and exhaust to the hall |

Cold air enters the cabinet through the bottom cover (the cabinet stands on an adjustable welded frame). The solid glazed front door keeps cool air in the front part of the cabinet. The separating frame and blanking panels effectively separate this cold air from the waste hot air. The expanded metal rear door allows hot exhaust air to easily exit the cabinet. Front glazed door with lever multi-point lock (universal key) Expanded metal rear door with 86% perforation rate and with lever multi-point lock (universal key) Removable metal side panels with lock (universal key) 2 pairs of vertical sliding rails Top and bottom cable entries, removable top cover Height adjustable legs; combined welded frame DP-PRF-ROF-60/60 (optional) |

| Recommended cooling systems | Recommended cooling systems for floor-based cooling with exhaust to the hall require a central cooling system. We have been an official partner of a leading global manufacturer of cooling solutions since 2008. This partnership enables us to offer sophisticated central cooling systems. Do not hesitate to contact us, we will be happy to assist you whether your project requires a simple cooling method or a massive central cooling capacity. |

PREMIUM Server RF1 is a new and unrivaled cabinet of the Premium series designed for the most demanding customers and modern data centers.

New types of rails with U-position markings are very easy to fix, offering an extraordinary degree of variability of the internal layout. An 86% perforated door can be opened up to an angle of 190°.

The RF1 cabinet is compatible with all CONTEG cooling, airflow optimization, and flexible cable management systems, as well as with many additional systems, such as access systems, PDUs, smart power, and fire extinguishing systems.

The portfolio of power distribution units (PDU) that ensure power distribution in high power density IT environments includes 3 types - controlled PDUs enabling control of individual sockets or their groups remotely via a data network, monitored PDUs enabling remote monitoring of the current drawn from the power supply panel via Ethernet /IP, and basic PDUs with no additional features.

The RAMOS monitoring system is used to monitor the internal and external environmental conditions (temperature, humidity, water leakage, smoke, etc.) in large data centers, server rooms or individual cabinets. The system is ready to integrate and monitor other devices, such as smart power supply panels (PDUs), uninterruptible power supplies (UPS), cooling units, etc. The system supports remote control. RAMOS includes 4 types of main monitoring units with differentiated sets of functions. The units support a different number of sensor and offer different number of inputs and outputs. All main monitoring units have a built-in web server for basic settings and can also be integrated into the CONTEG Pro Server application, which allows for central management, monitoring of the environment, and access using RAMOS hardware. Information can be transmitted over the following protocols: HTML, XML, SNMP, SMTP.