The aisle containment solution is often deployed in high thermal demand environments where cold air is directed directly to the cabinets.

A potential drawback of an open hot/cold aisle arrangement is the a potential lack of recirculation of heated air to the cold aisle and the associated risk of hotspot formation.

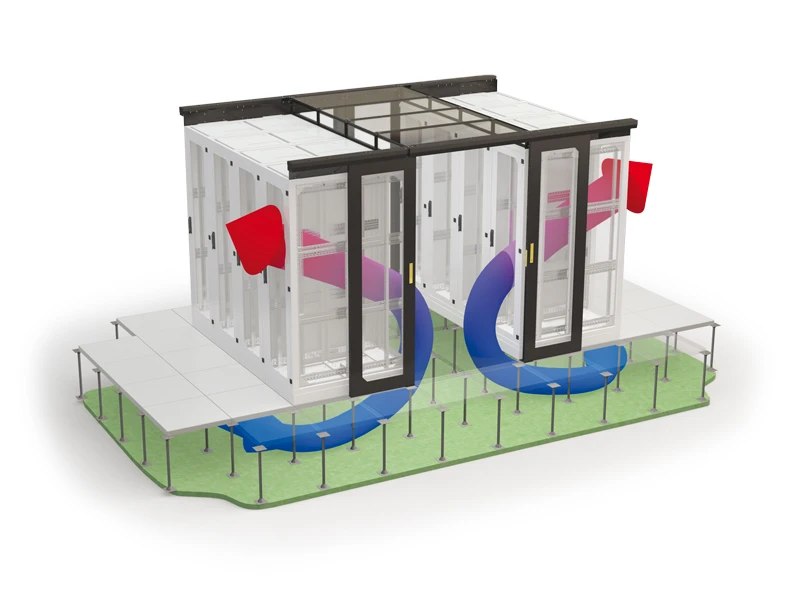

CONTEG’s cold aisle containment solution (CCA) is a sealed modular expandable system that physically separates and isolates conditioned air from hot exhaust, creating a cold air chamber and preventing the mixing of heated and cool air.

Cold aisle containment

Conditioned air is supplied to the aisle containment through perforated cubes from the double floor or locally by CoolTEG cooling units that are integrated directly in the row between the cabinets.

The standard width of the cold aisle containment is 1.2 m (two perforated cubes) or 1.8 m (three perforated cubes) and the aisle can be equipped with double sliding or standard (180° opening angle) doors. The use of a cold aisle containment is recommended wherever there is a need to maximize cooling performance while minimizing data center energy consumption.

We also offer a modular aisle containment available upon request, which is the ideal solution when you require an aisle with cabinets of different heights, with gaps between cabinets or incomplete cabinet rows. The system features a self-supporting structure with roof panels made of clear polycarbonate. The side parts consist of PVC slats fixed to the roof of the aisle, which can be easily shortened to the desired length. The modular aisle can be fitted with a standard double leaf door (180° opening angle) or PVC slats.

CONTEG’s aisle containment solution leverages a modular system that separates cold air from hot exhaust air to create an enclosed cold space. This space prevents the mixing of cold and hot air and eliminates hotspots. The aisle containment solution is often deployed in high thermal demand solutions where cold air is directed directly to the cabinets.

Recommended cold aisle containment configuration

| Parameter | Value |

|---|---|

| Width | Cold aisle containment is 1.2 m (two perforated cubes) or 1.8 m (three perforated cubes) wide |

| Height | Cold aisle containment is intended for 42, 45 and 48U CONTEG cabinets |

| Roof parts | Available in lengths of 400, 600, 800, 900 and 1,100 mm. The roof panels are made of clear polycarbonate to allow light to pass into the enclosed aisle space while meeting fire-resistance requirements based on the standards applicable to the site. The roof panels are ready for installation of fire protection devices that feed extinguishing medium into the aisle containment. |

| Side panels | With visors |

| Aisle entrance | Fitted with a one double-leaf, sliding or standard door (door opening angle 180°), 1,200 mm (1,800 mm) wide x 2,246 mm (1,800 mm) high on one side and one blanking panel of the same dimensions on the other side for closed-end aisles. If the aisle is through, it must be equipped with double doors at both ends. Doors can be equipped with manual or hydraulic door closers or automatic door controls with integrated access control, environmental monitoring and fire alarm systems to ensure that the door opens or closes automatically whenever required. |

| Perforated front door |

Allows excellent cold air flow into the cabinet, while the rear perforated door allows heated air to flow out of the cabinet; we recommend using accessories for proper air flow inside the cabinet - a separation frame and blanking panels.

|

| Auxilliary systems | Optionally, the aisle containment can be supplemented with an automatic door control system; this can be linked with access control, environmental monitoring and fire alarm systems to ensure the correct automatic opening or closing of the doors. |

| Aisle containment door | The aisle containment is fitted with a double-leaf door set in a metal frame (2210x620). The metal frame fixes to the cabinets at the end of the cold aisle. Once a sealing tape has been applied, both door leaves can be installed to close the aisle. The door is supplied with a handle and a locking mechanism, optionally with an automatic opening and closing system. |

| Aisle containment roof | Modular roof sections install on top of the cabinets, preventing the mixing of cool air inside the aisle with hot air in its surroundings. The assembly is made from 1.5 mm powder coated steel and is available in widths of 600, 800, 900 and 1,100 mm to fit any combination of cabinet dimensions. The vertical panels are paned with glass for maximum transparency, while the roof panels are made of 6 mm thick polycarbonate, which allows for easy integration with the cold aisle extinguishing system. |

| Automatic door opening system | We developed an automatic door opening system for easy and safe automated access to the cold aisle. The system enables remote control of the door as well as local operation using a push button or an integrated access control system. The automatic door opening system can be combined with the RAMOS cabinet monitoring solution, which sends an alarm signal in emergency situations and further increases the flexibility of the system. |

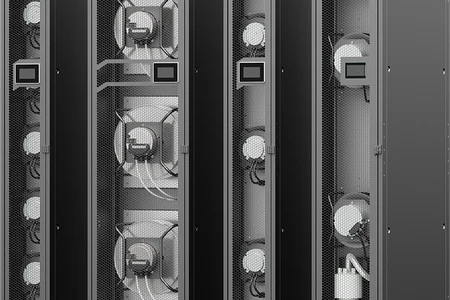

PREMIUM Server RF1 is a new and unrivaled cabinet of the Premium series designed for the most demanding customers and modern data centers.

New types of rails with U-position markings are very easy to fix, offering an extraordinary degree of variability of the internal layout. An 86% perforated door can be opened up to an angle of 190°.

The RF1 cabinet is compatible with all CONTEG cooling, airflow optimization, and flexible cable management systems, as well as with many additional systems, such as access systems, PDUs, smart power, and fire extinguishing systems.

CoolTeg Plus cooling units are designed for easy integration between IT cabinets. With different cooling technologies, dimensions and performance - they provide effective precision cooling, from a small server room to large data centers.

The portfolio of power distribution units (PDU) that ensure power distribution in high power density IT environments includes 3 types - controlled PDUs enabling control of individual sockets or their groups remotely via a data network, monitored PDUs enabling remote monitoring of the current drawn from the power supply panel via Ethernet /IP, and basic PDUs with no additional features.

The RAMOS monitoring system is used to monitor the internal and external environmental conditions (temperature, humidity, water leakage, smoke, etc.) in large data centers, server rooms or individual cabinets. The system is ready to integrate and monitor other devices, such as smart power supply panels (PDUs), uninterruptible power supplies (UPS), cooling units, etc. The system supports remote control. RAMOS includes 4 types of main monitoring units with differentiated sets of functions. The units support a different number of sensor and offer different number of inputs and outputs. All main monitoring units have a built-in web server for basic settings and can also be integrated into the CONTEG Pro Server application, which allows for central management, monitoring of the environment, and access using RAMOS hardware. Information can be transmitted over the following protocols: HTML, XML, SNMP, SMTP.